A sky full of drones swooping down to deliver packages, automated robots crowding sidewalks with pizza and grocery deliveries, autonomous trucks and rail cars shipping freight around the country. It could be a scene from the not-too-distant future, or could it?

A pair of industry experts presented on the latest technology in freight and goods movement during NJTPA’s Freight Initiatives Committee (FIC) meeting on October 20. Matt Soule, founder and CEO of Parallel Systems, explained advances his autonomous rail company hopes to achieve to get more trucks off the road. Daniel Smith, Principal at The Tioga Group, presented the realities and limitations of fully autonomous trucks and other vehicles, like delivery robots and drones.

Most sidewalk robots can carry the equivalent of six pizzas or about two bags of groceries, but none are truly autonomous to date as all are monitored, according to Smith. It is an urban technology that is limited in range and speed within a predictable infrastructure. Avride launched on the Uber Eats platform in 2024 and is piloting robotic deliveries in Austin and Dallas, Texas, and locally in Jersey City, New Jersey.

Suburban and rural areas are too dispersed and sometimes lack sidewalks for delivery robots to be effective. There are urban human and vehicle compatibility questions when scaled, Smith said. “What happens when you have lots of sidewalk robots sharing space with pedestrians on sidewalks, it will cause issues. It’s one thing to have one or two robots, it’s something else entirely when you’re trying to dispatch 100 robots.”

Autonomous Trucking

Smith outlined findings from a 2023 study on the state and local impacts of various kinds of autonomous and automated vehicle technologies, with a focus on freight.

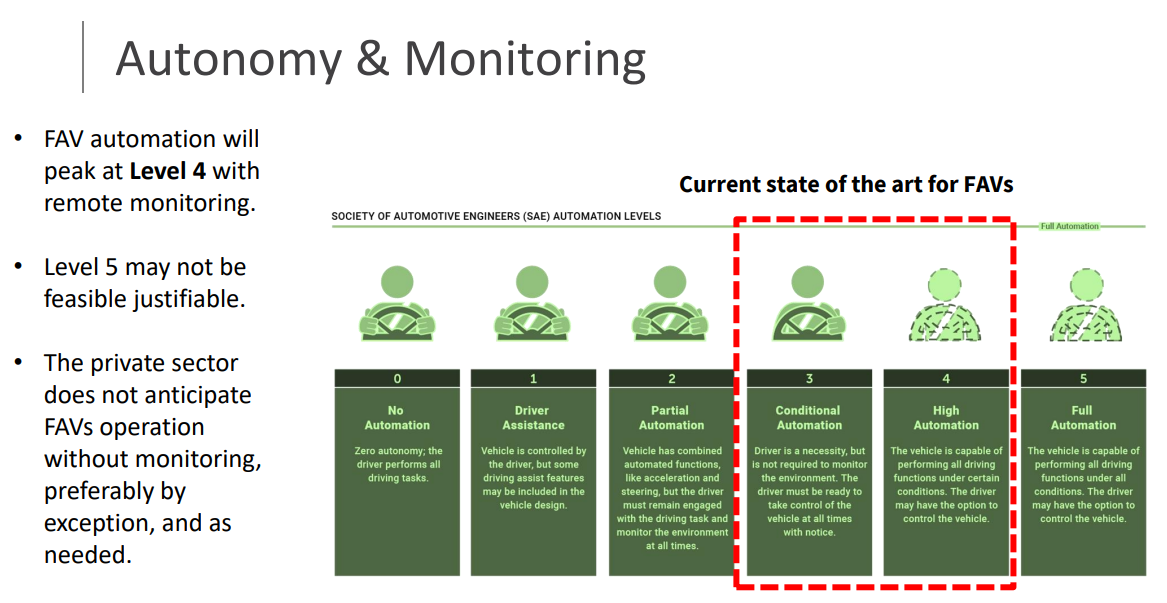

“Where we’re heading is high automation, not full automation or autonomy,” he said, describing high automation as Level 4, with full automation as Level 5. No one is pursuing full automation vehicles that will operate without human monitoring or potential intervention because the incremental cost of full automation is unlikely to be justified. “Everyone hopes to go to Level 4 solution where you can monitor them remotely,” Smith said. [Click to enlarge graphic to the right.]

There are many potential benefits to automation in the supply chain, from reductions in accidents to expansion of daily coverage but the main target is labor costs. For trucking, labor is the largest cost. “That’s where they’re looking to reduce costs,” Smith said.

“One side of the autonomous vehicles in particular that needs more emphasis is the expectation of safety,” Smith said. How many autonomous trucks it would take to realize the safety benefits is a question that likely won’t be answered for decades. It will be 20 to 30 years before significant fleet turnover leads to routinely seeing autonomous trucks on the road, Smith said.

Another issue: There’s no anticipated data swapping between vehicles or between vehicles and the public sector. “You’re not going to get additional data on freight operations,” Smith said.

Autonomous Rail

Parallel aims to cut into the roughly 10:1 difference in freight market size for trucks versus rail by addressing barriers for shippers. Those barriers include service quality, not necessarily speed, but “being consistent and being regular,” Soule said. “Most importantly, we want to solve for the lowest cost,” he said, always a relevant issue for moving goods.

Parallel is developing a battery electric autonomous vehicle where no locomotive is required. Platoons are more energy efficient, mechanically pushing from the rear and “physically amortizing the drag” that the lead vehicle sees, Soule said. A designated lead car is “the eyes and ears of the platoon.” There are still people required to build and maintain track, load and unload containers, and new jobs being created to oversee operations from the convenience of an office.

Soule said they’re working with railroads around ports to connect ports directly to warehouses. “This is a big cost reduction and a big opportunity to decongest some of the truck traffic that comes in and out of ports.”

A pilot in southern Georgia received Federal Railroad Administration (FRA) approval to start in January, that’s now in the late stages of Phase 2, according to Soule. It’s “an opportunity to verify and validate safety controls in a real-world environment,” he said.

“Density matters for a lot of these technologies,” Soule said. “We’re not going to make sense for moving one container to a factory one time a week, it’s not going to pencil. But there are many warehouses that are doing hundreds of containers a week, which is significant.”

A recording of the FIC meeting is available via the NJTPA YouTube channel.